In about a month, we’re making the leap to become liveaboards at Shilshole. We haven’t decided for how long, but will re-evaluate at one year – it’ll come down to how well we survive the difficult winter months when it’s rainy, cold and dark every day.

There are some big reasons making it worth trying the liveaboard lifestyle, and an equal number of fears / worries we have about it. It’s not right for everyone, but everyone we talk to who has made the jump to being liveaboards loves it and recommends it.

To me “liveaboard” means living on a boat while being tethered to one home port most of the time – either because you have to work a job on land, or perhaps you’re retired but just don’t want to go anywhere. Although last summer we lived on the boat for 3 months, that was cruising – which is living aboard while traveling, an entirely different matter.

Moving aboard involves lots of full carloads – to both the boat and storage

The storage locker already getting pretty full – we need to start stacking higher

The benefits to liveaboard life are clear:

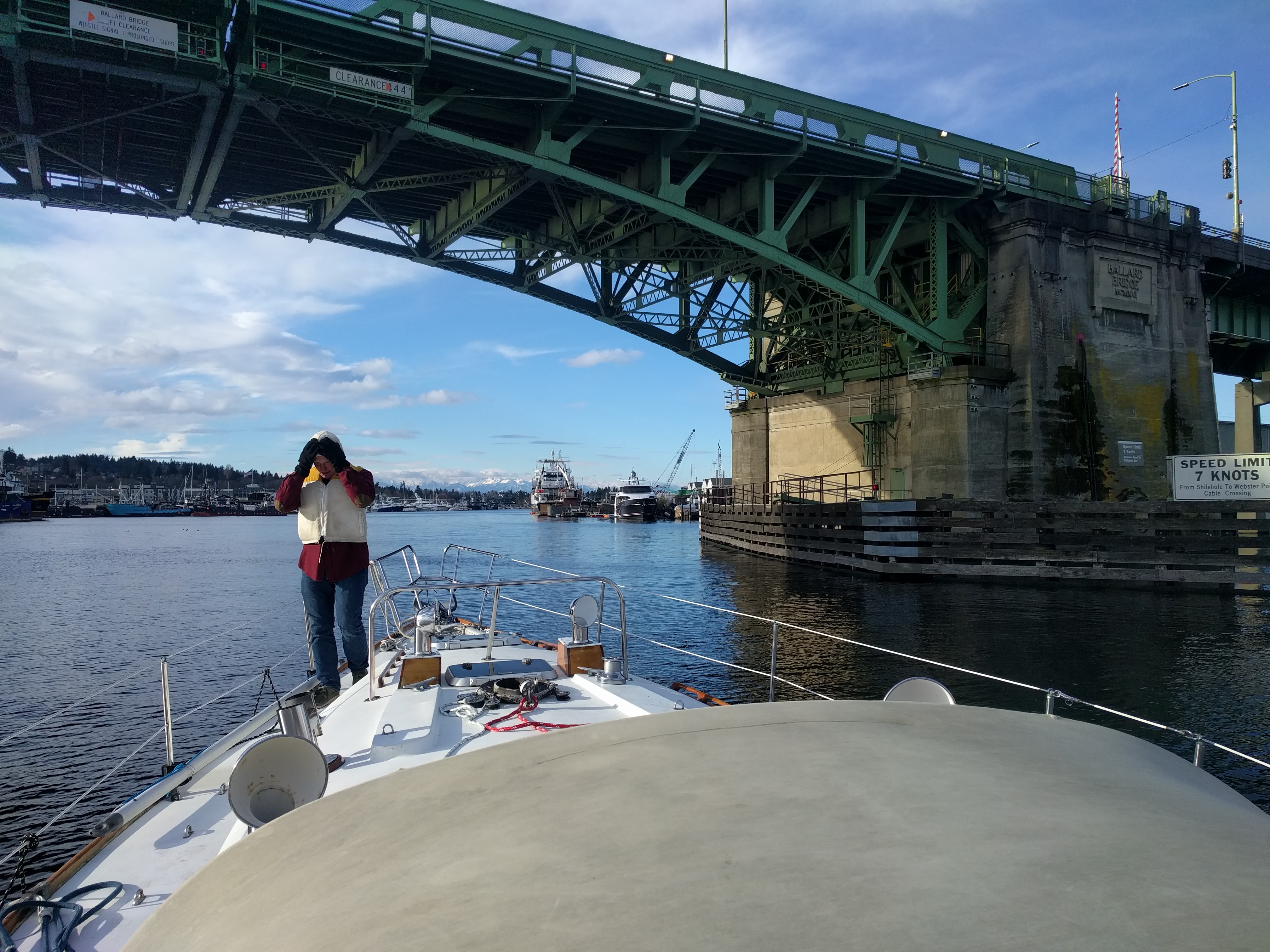

- Waterfront real estate. Living in a marina, your home is in a beautiful waterfront location with views of the snow-capped Olympic mountains and wildlife (sea birds, seals) passing by your back porch (cockpit).

- Money. Not many people discuss this, but I think the biggest advantage of living aboard is how much money you can save. With Seattle’s surging real estate market, a nice 1-bedroom apartment in the city can run about $1500-2000. Liveaboard moorage for a 38-foot boat runs about $680. That’s a savings of up to $15,000 per year, which can be put towards cruising, vacations, or paying off debt.

- Living life in a more Minimalist way – less consumerism, less stuff, less distraction.

- Efficiency. We’ll no longer need to commute between an apartment and the boat to do project work or go sailing. This saves time and may make certain types of projects easier. We’ll no more have a “boat pile” at home and a “home pile” at the boat.

- Carbon Impact. Living on a boat is a very earth friendly way to live. On the boat, we use a fraction of the electricity we use at home, a tiny fraction of the amount of water, and produce less consumerist discards (trash/recycling) due to the forcing function of having to live in a minimalist way.

There are also a few fears we have about living aboard:

- Will it make us end up sailing less? When your boat is your home, it’s more work to get it shipshape for sailing. Not only that, since it’s our only home, we can’t easily go sailing separately – if I want to go out sailing while Natalie is at work, a happy hour, or just doesn’t feel like sailing that day, she won’t have anywhere to return to after the event.

- Storage – will having massively less space to store stuff be a considerable burden?

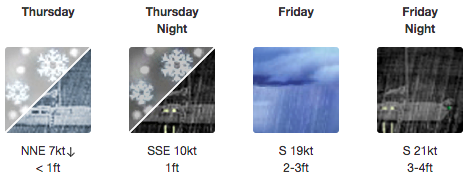

- Will the wet, rainy weather we get for weeks on end (before the summer starts) be tiresome? Will heating be a problem?

- Commute – my commute gets slightly better (biking between Ballard + Fremont rather than Capitol Hill + Fremont) but Natalie’s gets worse. Getting to downtown from Ballard isn’t easy. She can drive in 20-25 minutes on an early schedule, but then has to pay $30/day for parking. Public transit involves a 1 mile walk followed by 2 buses, totaling about a 1 hour commute. Biking is an option but also takes close to an hour. Any Ballard-Downtown commuters know of better options?

- When we go cruising now, being on the boat in anchorages is truly special. Will that experience lose its magic when being on the boat is a more routine, everyday occurrence?

As with any change in life, there are some scary aspects, and some exciting aspects.

We’re currently working on massively downsizing – selling possessions on Craigslist and giving carloads full to Goodwill – much like we did last spring before renting our place for 3 months. But this time we’re also selling our condo, which means getting rid of all our furniture too. We have a small storage locker we’re using for keepsakes, winter clothes, ski gear, etc.

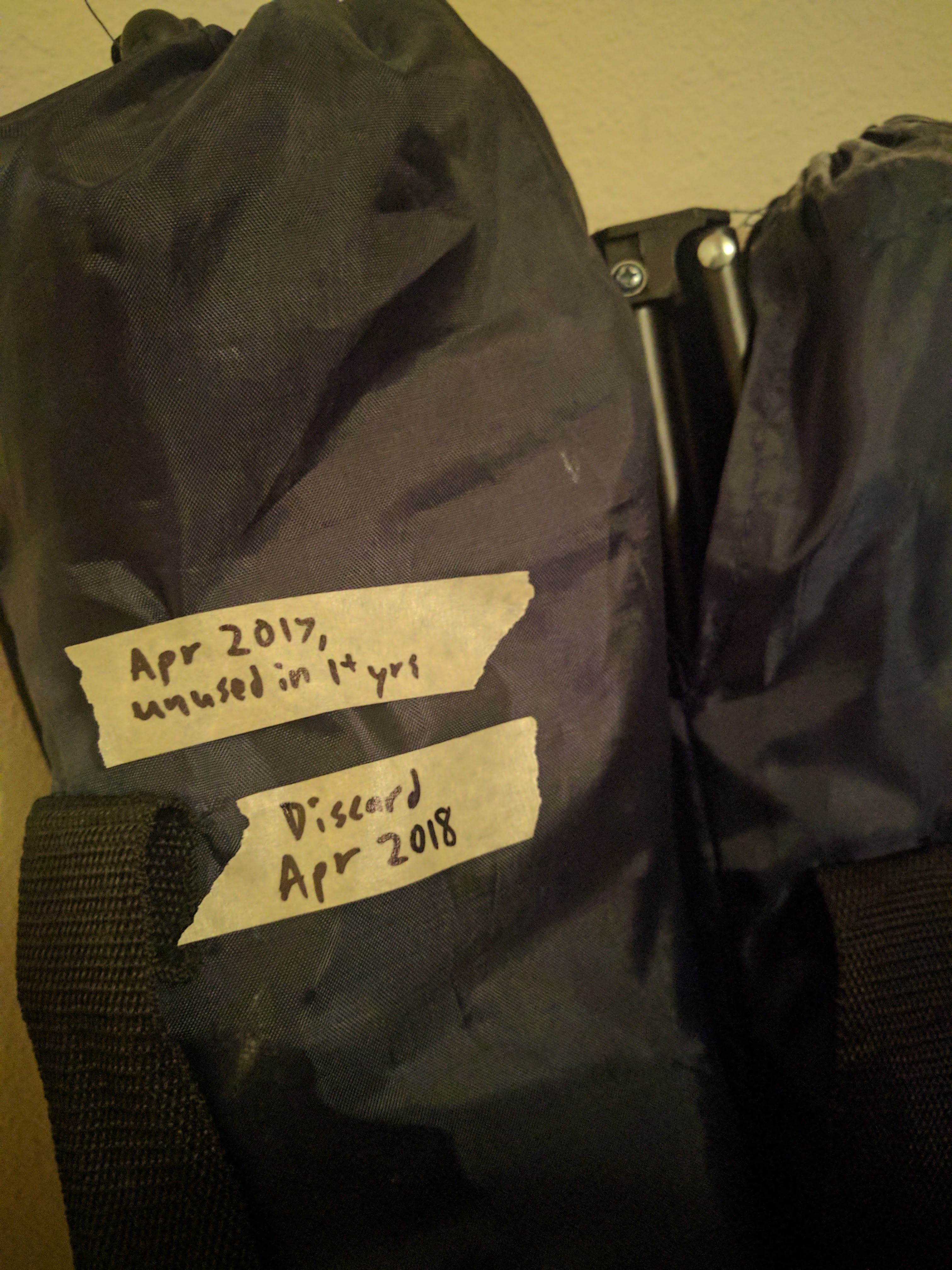

When you can’t agree on whether something that hasn’t been used in a long time is worth keeping, put a note on it marking a discard date – if you still haven’t used it in X amount of time, then clearly it wasn’t really needed

It’s strangely liberating to get rid of so much stuff. You don’t realize how much you have until you do it. Further, you don’t realize how much of a disposable purchasing society we live in. People buy so much stuff they don’t really need that it means possessions are not treasured, and Goodwill gets piles of barely used stuff every single day. Some things are impossible to sell on Craigslist because they’re not valued.

Despite a lot of work, we’re still getting out sailing about twice a month!