As I set the sails in Elliott Bay under blue skies with a perfect 8-10 knot breeze at my back, it was hard not to feel overwhelmed with joy at the successful completion of our haul-out. In five days we (myself + the yard) had gotten a ton done, nothing had gone wrong, and the haul-out was completed on schedule. Amazing. And no leaks!

It felt really good to have the boat back in her natural element, and as we glided smoothly along I noted it felt faster than before – probably thanks to the freshly painted bottom and prop, but more testing is needed to say for sure.

If you’ve ever done boatyard work, you know that haul-outs are stressful times. In a short period of time we take the boat out of water, do some of the most critical projects of the year and also incur our biggest expenses of the year (in one week, a haul-out doubles our yearly maintenance cost). It’s easy to see why some people avoid / postpone them as long as possible. But we want to get the boat into prime cruising condition, and delaying bottom paint any longer wouldn’t have been good.

In 4 days at Delta, the following work got done:

- By yard:

- bottom paint – 1 coat Pettit Horizons (went with this paint because it’s what was on before), doubled up on rudder and edges of keel

- prop + prop shaft cleaned and coated in PropSpeed

- 2 thruhulls / valves replaced

- 1 thruhull pulled and fiberglassed over

- By me:

- AutoProp regreased

- new anodes

- all seacocks regreased

- Raymarine depth/speed/temperature triducer replaced (the temperature function failed, and Raymarine was gracious enough to honor the warranty a couple months past 2 years).

- Replaced our overboard toilet discharge line and lubricated the y valve (the Raritan y valve was awfully hard to turn even though it’s only 2 years old!).

- Fixed a small leak in our port scupper seacock. Permatex thread sealant with PTFE for the win.

- Assist with yard jobs – mostly things like pre-prepping the thruhulls (removing hoses, clearing access), finishing work (reattaching hoses) / cleanup, and holding thruhulls from the outside so they don’t spin while screwing on the ball valve.

Our 3rd haul-out was in stark contrast to our first two, where after the first one I had two slow leaks from seacocks I had worked on, and the second one was beset with delays, scope creep, and a shortage of yard assistance. Admittedly, this haul-out was simpler as the tasks were more straightforward – so I expected things to go better. But it was a real relief to get out in 5 days with everything done and nothing gone wrong.

A short haul-out was a priority this year now that we live aboard. Natalie had a co-worker friend in West Seattle who was super nice in letting us stay in a spare bedroom of their house.

Out with the old…

… and in with the new.

The Yard

Not many Seattle sailors know about Delta Marine. Most go to one of the big three – CSR, Seaview, Canal. We heard a recommendation from our cruising club (PSCC) and decided to give it a try mostly because their labor rates are much lower than other yards – $73/hour instead of $100-110/hour. And their bottom paint package rate which includes the round-trip haul-out and pressure wash is pretty competitive.

Delta builds superyachts, but they also have a small boat yard next door which is run mostly as a separate operation. It was pretty amazing seeing some of the 150’+ superyachts being worked on next door – really makes our 38’ boat feel small in comparison. Some people we talked to assumed that’d mean we wouldn’t be a priority, but that wasn’t our experience. In fact the opposite – since Delta’s small boat yard has fewer boats than the busy north Seattle yards, it was easier to get the labor resources needed. They also have a lot more overall resources to pull from because the big boat yard has close to 50 people per day working in it.

We didn’t end up saving money on the mechanical labor rate, because the thruhull replacements took longer than comparable replacements done two years ago in a northern Seattle yard. So the $73 vs $100-110 was a wash. Getting boatyard work done on a budget is incredibly difficult – labor hours can stack up quickly, and it’s difficult to verify them. Somehow 3 thruhull replacements (one as a fiberglass close-up) took 29 hours. I’m still trying to understand that. We also got billed for 5 hours of bottom sanding even though no bottom sanding was necessary, or even done as far as I can tell.

So while our experience in the yard was very professional, the billing afterwards came in much higher than expected.

Getting To Delta

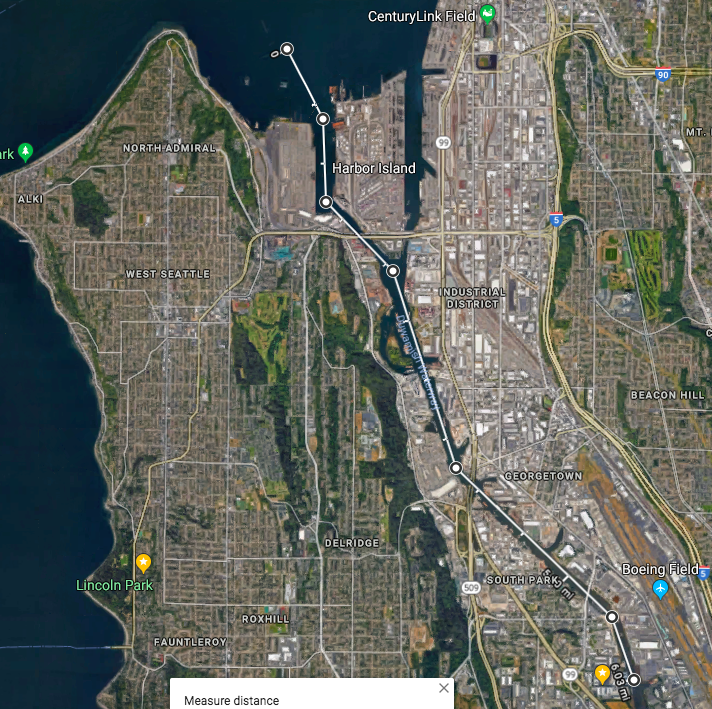

Getting to Delta from Shilshole is a bit of a trek. It’s about 12 nm from Shilshole to the entry to the Duwamish, which we did by sailing – into a 20 knot southerly with wind against current. 🙁 Then a ~5nm motor through the narrow Duwamish, raising 2-3 bridges. And there are some things to watch out for that you might not normally think of: shallow depths outside the dredged channel (haul-out will be scheduled near high tide), and a sometimes strong outflow current from the Duwamish River.

Our trip down the Duwamish showed us a side of Seattle we don’t normally see. Lots of barges and industrial work.

The Bridges

A note on the bridges: many of them either can’t hear or don’t respond to horn signals. With the sounds of traffic and frequent jets passing overhead (on the route to Boeing Field + Seatac), the bridges couldn’t hear my puny manual push-style horn. So I ended up calling on VHF 13 and they didn’t seem to mind that at all. On the return trip I just used 13 by default, sometimes doing it a couple minutes ahead to give them time to prepare.

Another thing to note about the bridges is on weekdays they don’t open from 6-9am and 3-6pm. This is 1 hour more on each period than the Ballard canal bridges. Weekends they open anytime though, so we headed down on Sunday because Delta allowed us to stay on their guest dock for the night – this made for much easier timing for the Monday morning haul-out.

Spokane Street Swing Bridge

This northernmost of the bridges was a question mark for us. Its height is just close enough to our mast height that we could probably clear it at low tide but not at high tide. Our Internet-looked-up clearance is 52’, and the bridge clearance is 55’ at mean high water. Confusingly, our Navionics charts say the clearance is 45’, but I think that’s a charting mistake. The bridge has a tide marker at the water, and we could see one time we had 60’ and one time had 55’.

We ended up opening the bridge both times. The reason to be cautious is your boat’s published clearance isn’t necessarily it’s actual clearance. Masthead instruments like VHF antenna can add 2-3’, and you probably want to leave at least a 2’ margin of error for tide mis-readings or waterline differences (if your boat is high in the water due to being lightly loaded).

And I’d like to actually measure our clearance height, not just trust a number looked up on the Internet. Another note is that “mean high water” means average high water, not extreme high water – on super tides there may be less clearance than the published mean high water clearance of 55’.

The Spokane Street swing bridge is also unusual in that it’s the only bridge we’ve ever gone under where the road swings out rather than going up! Make sure to stay clear of its swing radius. The bridge operator cautioned me about this when I got a bit close on the south side – there’s less room to maneuver there, and a 2 knot outflow current pushing me towards the bridge made my turns a bit wider.

Harbor Island Marina

We made the mistake of trying the Harbor Island Marina (Port of Seattle operated) for a pump-out. There was a strong current perpendicular to the docks, and a tug was permanently moored on the 30-minute-max pump-out dock, blocking about 1/4 of the dock – making for a tight fit with our 38’ boat and a 2 knot current pushing us sideways.

We decided to try going to the other side of the dock, *inside* the marina, and nearly got pushed into another boat. Current was ripping through the marina, and it’s the closest we’ve ever gotten to hitting another boat. The current swung our bow, fast, and we did a standing turn in just about the length of our boat, sandwiched between two other boats. Man were we glad to get out of there!

This was our lesson in Duwamish currents: even though we were entering on a rising tide which should’ve meant an inflow current going with us, when there have been many weeks of rain recently (and river flood warnings), the rain overpowers the tide and creates an outflow current all day long.

Conclusions

Astute readers might be wondering why we’ve been working on thruhulls for 3 years running now. Mainly the reason is we spaced them out – we had 10 (9 now) and replacing a thruhull / seacock is expensive. It’s also debatable how important it is. There’s a lot of hyperbole online about thruhulls. Over the last 3 years I’ve learned there’s no right opinion on how to do a thruhull (but everyone who has an opinion thinks their’s is correct and proper).

The main issue we had is our plywood backing plates were wet. So with these last 2 replacements we’ve replaced all of our leaky thruhulls and finally have a 100% dry bilge (except when rain comes down the mast of course). The 3rd thruhull which we had the yard seal up was an unused thruhull (probably a former owner had air conditioning?) which I wanted to inspect because it was installed in a location of the hull that was probably balsa cored. And I didn’t know if the former owner had done a proper job of sealing the core.

Upon pulling it, we found the hull was cored there as I suspected, and he had not sealed the core. Also the thruhull had been installed on top of bottom paint, which is improper because bottom paint erodes and could compromise the sealant earlier. So it was good I decided to pull this one – a seawater leak into hull coring can become a major issue.

After the yard opened up the thruhull more to the inner fiberglass skin, preparing to seal and close it.

Coming up soon I’ll talk about the work I did on our AutoProp, which is long enough to need its own post.

Ugh, I have to haul out soon as well and do a bunch of stuff, including seacocks. Mine haven’t been looked at since I got the boat, luckily I only have four (soon to be three when I pull one)

Wow, only 4 seacocks is nice. C&C liked to run scuppers below waterline, so that accounts for 3 of ours.

Great notes about the Delta yard, that sounds like a much better option for haul outs. I used Seaview last year and have no complaints compared to years previously. It was a bit expensive, and there were a couple of delays because of how busy they were, but at least it wasn’t the “old” Seaview from 5 years ago, which I avoided like the plague. CSR is nice too, but I don’t want to have to go through the locks, and deal with their schedules.