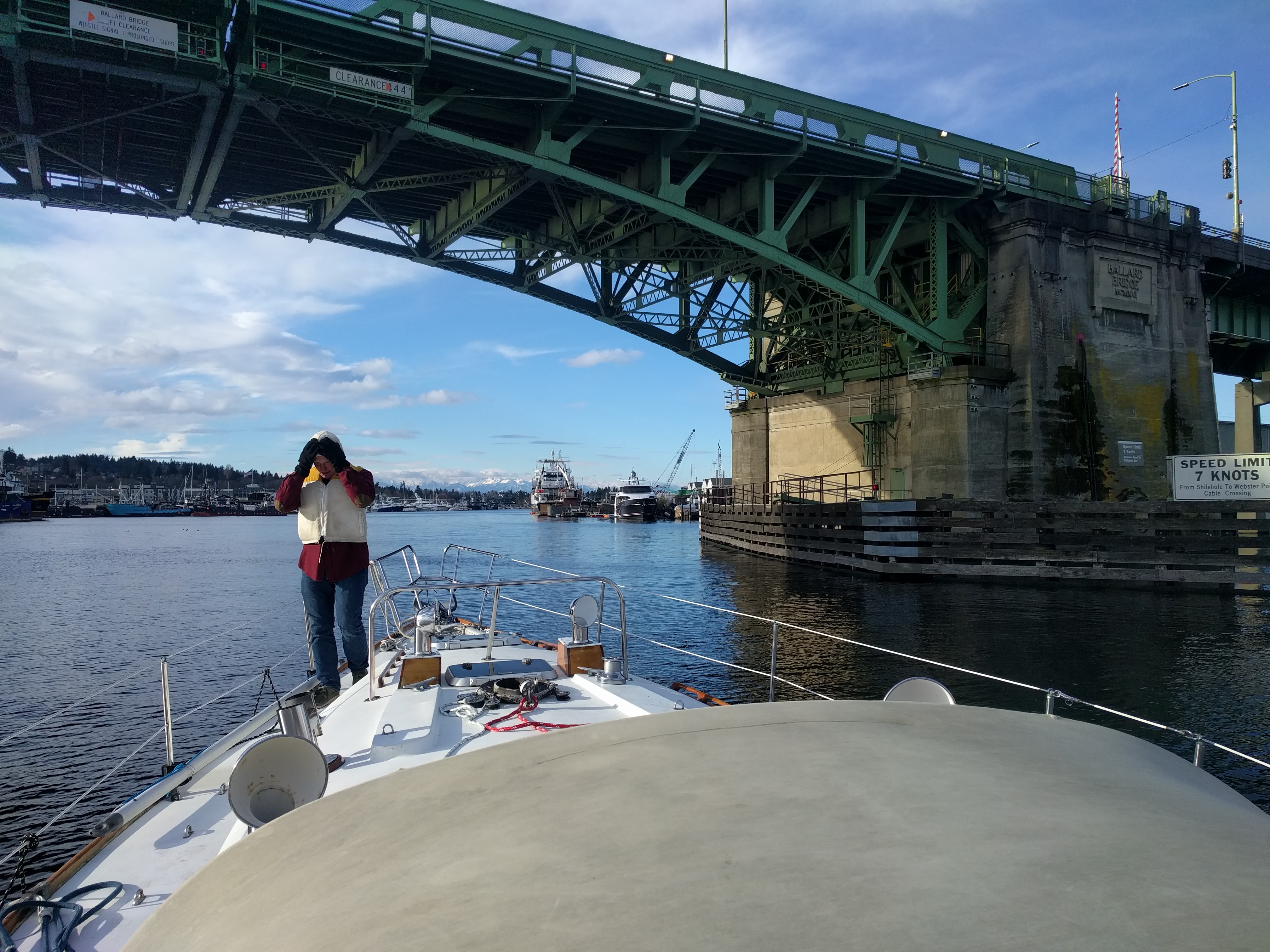

As the Ballard Locks attendant checked our lines, he remarked “Where’s your mast?” I replied “Oh, I knew we forgot something! We’ll have to turn around.” This was actually all part of the plan – an hour ago we had passed under the Ballard Bridge – without raising it! We had left our mast at Canal Boatyard for the next phase of the rerig.

Seeing the mast come out of the boat was a bit unnerving – but it all went really well. It took only 30 minutes to pull the mast, thanks to two days worth of prep work – but that work had actually been pretty fun. We were lucky that nothing was seized or really difficult to get apart. It was mostly a matter of unscrewing bolts, straightening cotter pins, removing the sails and boom, and doing one last climb up the mast to attach the crane’s sling.

Our least favorite part actually was going through the Ballard Locks – that’s pretty much always nerve racking. The small locks got filled by a 70’ motorboat, so we had to wait an hour for the big locks, maintaining position in strong currents between the locks and the lowered railroad bridge. Then on the way back west, the Argosy cruise came up behind us and got priority on the small locks, adding another long wait.

Passing under the Ballard Bridge with no mast

Prep Work

Most of the work of pulling a mast is in the prep work. For us this took about two days (only two 5-6 hour days though). For our boat the steps included:

- Drop genoa and fold. Remove main sail and fold.

- Remove the boom – including disconnecting the rigid boom vang, reefing lines, lazy jacks and main sheet.

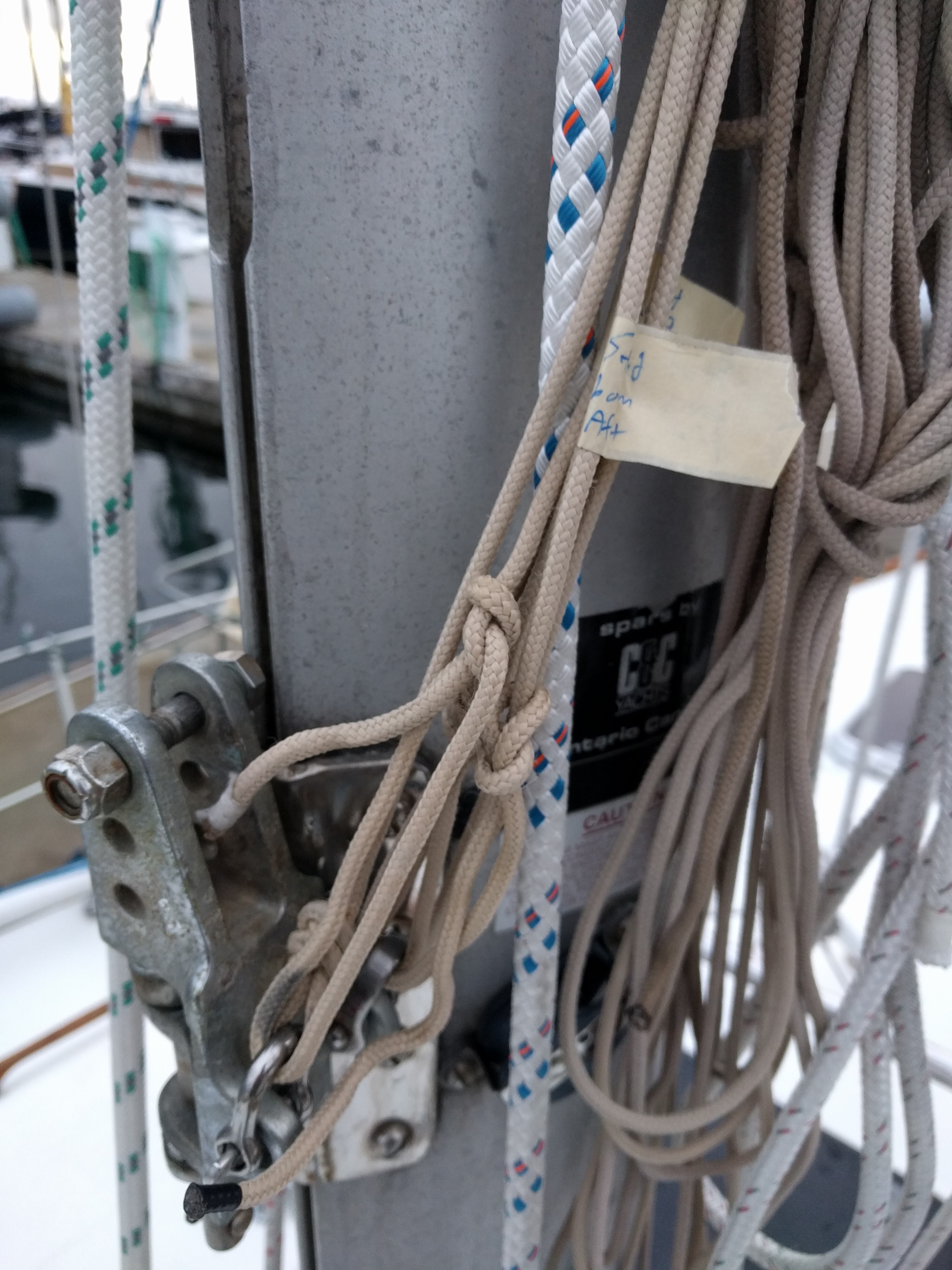

- Stow halyards on mast.

- Remove cabin table that is sandwiched around the mast.

- Loosen and raise the mast boot.

- Disconnect mast partners (stainless steel bolt attaching the mast to the deck).

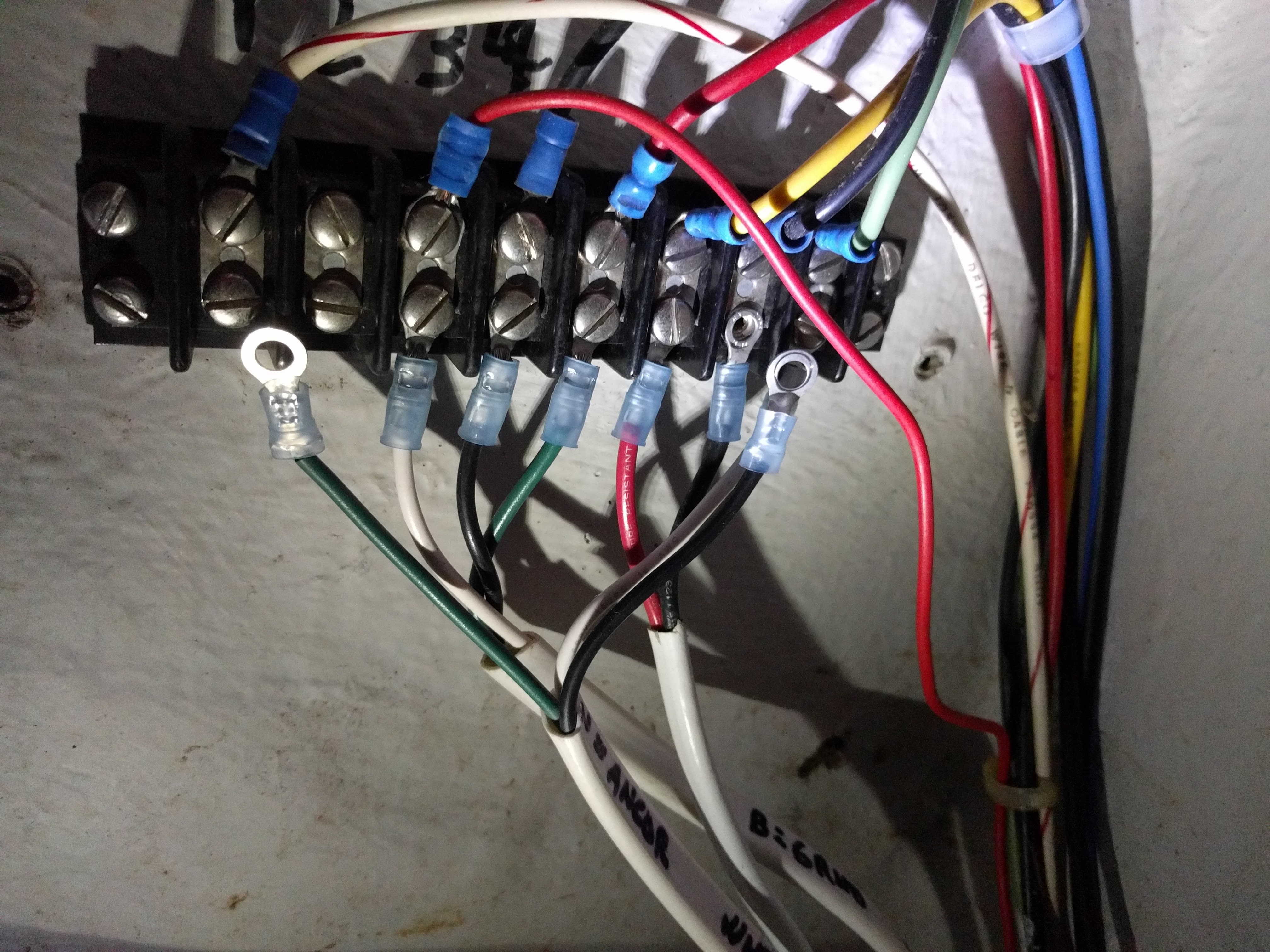

- Disconnect mast wiring.

- Attach tag lines to the mast base and furler. (this proved to be unnecessary).

- Straighten all cotter pins in clevis pins at deck level of stays that you’ll need to release.

- Mark (tape) the turnbuckle positions so we know the tuned length if we need to remeasure in the yard.

- Loosen turnbuckles until the rig is moderately slack.

You’ll want to make sure all your mast wiring is well labeled (or at least take a picture of it)

Securing halyards and labeling the lazy jack attachment points

Boom is down and secured

Pulling the Mast

Pulling the mast took only 30 minutes, because we had all the prep work done beforehand, including loosening all the shrouds (our mast is keel stepped) and disconnecting the four lower stays.

We had three people onboard, plus the two yardworkers, and this ended up being perfectly adequate.

The yard did want me to climb the mast to attach the crane sling, and couldn’t lift me on the crane hook, for liability reasons. So I’d recommend keeping the main shrouds, forestay and backstay not completely floppy, and keeping the main halyard ready.

Cutting Nitronic 50 Rod

The next step was fun because it gave me an opportunity to test some safety equipment – in case you ever have a dismasting, many cruisers recommend having a way to cut your rigging. If you don’t have an easy way to detach it from the boat, in a heaving sea with chaos all around, the mast or rigging can hole and sink the boat. For this emergency scenario I had a 14” bolt cutter on board – primarily as a handy tool for project work, but also could be used in a pinch for cutting rod. But I didn’t know whether that would actually work – 14” wire cutters are relatively small, and Nitronic 50 rod is very strong.

The reason I was cutting the rod is it’s the only way to get the tangs off, and we decided to just ship the tangs, along with measurements, rather than shipping coiled rod, which is a big pain and higher shipping expense.

Here’s what I found:

- 14” bolt cutters worked for cutting -8 rod (8000 lb breaking strength, similar to 1/4″ to 9/32” 1×19 wire), used on my fore and aft lowers. Some serious brute force was required, levering one cutter handle against my knee, but it only takes about 5 seconds to make the cut.

- The wire cutters didn’t work for -10 rod (main shrouds, forestay, backstay). The -10 is simply too thick and tough. But I found a Dremel with the fiberglass cutoff wheel worked quite well – it took only about 30 seconds.

Two cuts used up maybe ⅛ – ¼ of the wheel – but these Dremel wheels are basically a consumable item – if you’re doing more than 2 cuts I’d recommend having a couple wheels on hand. - My Fein Multimaster (oscillating tool) with a bi-metal blade didn’t work for cutting -10. It made it ⅛” deep and then the stainless steel rod dulled / destroyed the teeth of the Fein bi-metal blade. I thought the Fein would be quicker than the Dremel, but definitely wouldn’t recommend it for this job.

- I briefly tried a hacksaw, but it was so slow I couldn’t tell if it was doing anything.

In the future I think I would use the Dremel as my primary, and perhaps only, emergency rig cutting device. It does have the disadvantage of requiring charged batteries, but I generally keep it charged while cruising. The only other option for -10 rod would be getting bigger bolt cutters, or a hydraulic cutter.

Navtangs

Navtangs are the Navtec brand mast tangs that attach Navtec rod rigging to the mast. A big concern riggers and sailors have when rerigging a rod boat is that the Navtangs can be seized and hard to unscrew. Older Navtangs were made with aluminum tie rods, so many people assume that all Navtangs have aluminum screwed into stainless steel, which will almost certainly be seized. Newer Navtangs had stainless steel tie rods though, and my boat has that variety.

I already knew my intermediate navtangs came apart by hand (from a project last year) so I was hopeful the others would too. And as luck had it, they came apart like butter! I was able to unscrew all three with only a couple fingers on a 5” long hook spanner wrench. Whoever put these together did a good job using an anticorrosion compound. Furthermore the Navtangs were in excellent shape.

Replacing Masthead Sheaves

While the mast is out I want to replace the old wire-rope sheaves that the main and jib halyards are on. Wire-rope sheaves have a groove in the middle where the metal wire would sit, from the days where people still used combination wire-rope halyards. My rope halyards still work fine on these sheaves, but the rope doesn’t sit as well as it would with a proper sheave and it likely causes faster wear (I noticed some black marks on the new halyards after only a few months of use).

The sheaves are installed with an interesting clevis pin design – apparently pretty common – where the clevis pin comes out the mast on only one side, with a stainless steel cover plate welded to the clevis pin and secured to the mast with a machine screw (so the clevis pin can’t pop out).

The machine screws were pretty seized from corrosion, and the cover plate apparently was welded with a pretty small surface area to the ½” clevis pin (only about a ¼” weld). As I was trying to pry/rotate one cover plate off, the plate sheared off the clevis pin. So now I have a clevis pin seized / stuck inside the mast.

But this is a small problem as these things go – my plan is to drill and tap the clevis pin for a ¼” screw and drive that in to pull out the clevis pin. That tapped hole will also be how I reattach the cover plate, which seems superior to welding anyway, since that has proven to not be foolproof.

I’m getting the new sheaves made from ZephyrWorks in Port Townsend. He makes Delrin (the brand name of a type of hard acetal plastic) sheaves in any size, with a pretty quick turnaround.

Conclusions

This project is a lot of work, but so far it’s been very rewarding. If anything it’s given me a new appreciation for how well built and well designed the C&C is. Even after 34 years, our rig was in surprisingly good shape. Partly that’s thanks to the boat never having been in a tropical climate, but also thanks to Nitronic 50 rod being amazingly durable and rust resistant. I now have way more confidence in rod lasting much longer than a wire rig.

And it’s been great becoming intimately familiar with the rig – a rig is the heart of a sailboat. The amazing engineering behind a sailboat’s rig is what provides us the motive force that allowed us to coverage so much mileage by sail last summer.

Coming Up

We still have a lot of work to do. Next up (Part 3) is pulling the chainplates and getting out a seized clevis pin in the bow that has been with us for over a year.

Great tips. I am going to save this for when we get our mast done next year!

This was exactly the information I need. Same problem with the sheaves. Almost took off the axle keeper. I’ll be pushing it out and sealing my access hole!!

Charles

Port Townsend Rigging (PTR) builds rod standing rigging locally – they will pick up the old rigging and deliver the new rigging to the Seattle area. Cheers!

Are Dan and Lisa still the owners working at PTR? I spoke with Lisa back in 2016, we were discussing whether a $4000 addtl cost was worth it, and Dan came on in the background saying it was “minutely cheap” and “He’s not listening, I can’t deal with this.” He was condescending and dismissive. Ruined my day. Realized I couldn’t work with someone like that. I contracted with Cliff Hennan at Evergreen Rigging and he was great.

Hi Patrick,

Sorry to hear about your experience with the past owner’s of PTR. I took the helm of PTR about 3 years ago and strive to provide a better experience for our clients. Happy Cruising! PTR

Oh, I thought there might have been an ownership change but couldn’t find any news in a quick Google search and website check. Good to know, I will certainly take that into account in future recommendations if anyone asks!